Innovation and trust in agricultural aviation since 1997

Sérgio Zanoni began working in agricultural aviation alongside Teruel (Campo Grande-MS).

Sérgio and Graziela founded Zanoni Agricultural Pumps & Equipment, producing water wheels in NW Paraná and Mato Grosso do Sul.

Founded Zanoni Agricultural Equipment in Paranavaí, focusing on aerial application.

Produced Brazil’s first stainless-steel wind-driven pump.

Began supplying equipment to Neiva/Embraer.

Started manufacturing pumps for self-propelled sprayers.

Built our current headquarters (still smaller than today’s scale).

Made Brazil’s first stainless-steel pump for Air Tractor.

First exports (South Africa and Argentina) and Brazil’s first aerial firefighting gate.

Began partnership with Canadian Ag-Nav.

Produced Brazil’s first stainless-steel engine-driven pump.

Produced Brazil’s first stainless-steel hydraulic gate.

Started manufacturing rotary atomizers.

Second generation of the family joins company management.

First international dealerships: Guatemala, Argentina, USA.

Scaled industrial supply of pumps and start of aerial firefighting boom in Brazil.

Agricultural boom: Zanoni equips 100+ new aircraft per year.

Expanded field presence through workshops, research funding, and seminars.

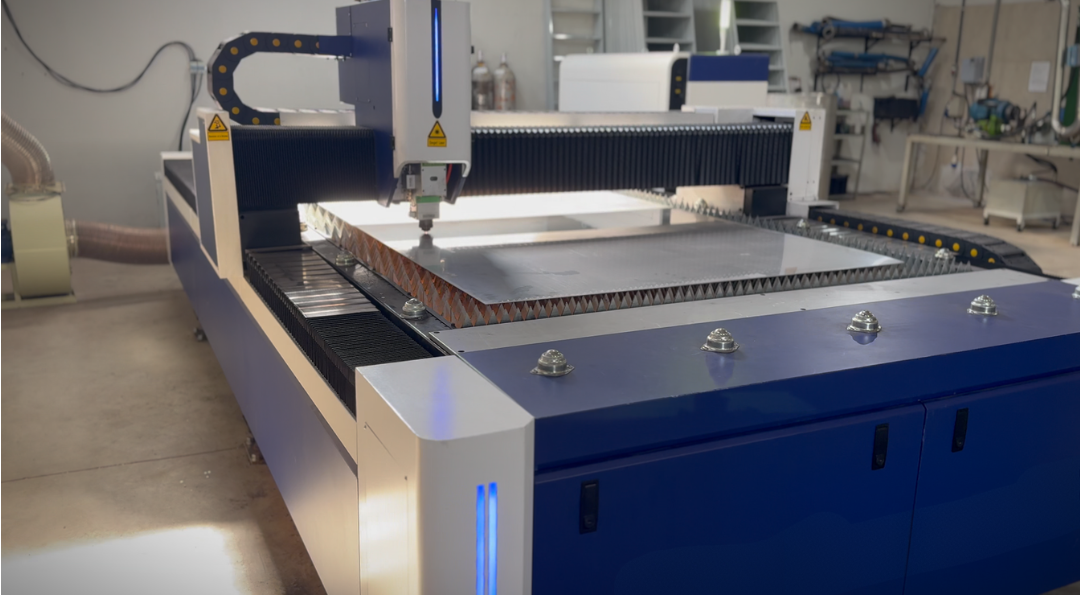

Factory modernization and major capacity expansion.

Consolidated global leadership in aerial application technologies.

Launched solid dispensers, pre-mix tanks, and electronics production.

ANAC issues Production Organization Certificate (COP) to Zanoni.

Generate profitability and safety in the field through R&D of quality products.

Be a global reference in the aero-agricultural sector.

From left to right: Juliano (Commercial), Bruna (Quality), Lucas (R&D), Raíssa (HR), Sérgio (CEO), Graziela (CFO), Laura (Baby), Letícia (Supplies) and Vitor (Planning).

“From the trust that united two cousins in agricultural aviation in the 1980s to a couple’s dream of securing their children’s future, growing recently through siblings and in-laws—now with a third generation on the way. Inside and outside Zanoni, we treat everyone as part of one big family; it’s this trust that seeds partnerships and yields our success.”

Comprised of four industrial buildings along BR-376, our location connects Brazil’s South, Southeast tech hub, and the booming Midwest agricultural region.

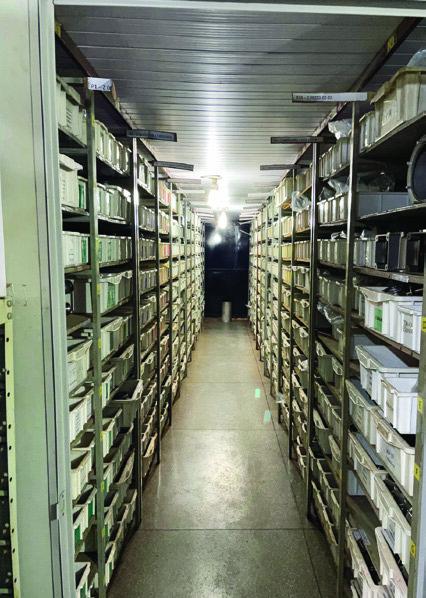

Our production includes CNC lathes and high-precision machining centers, laser and waterjet cutters, world-renowned welders, meticulous assemblers, and a stock of over 5,000 product types.

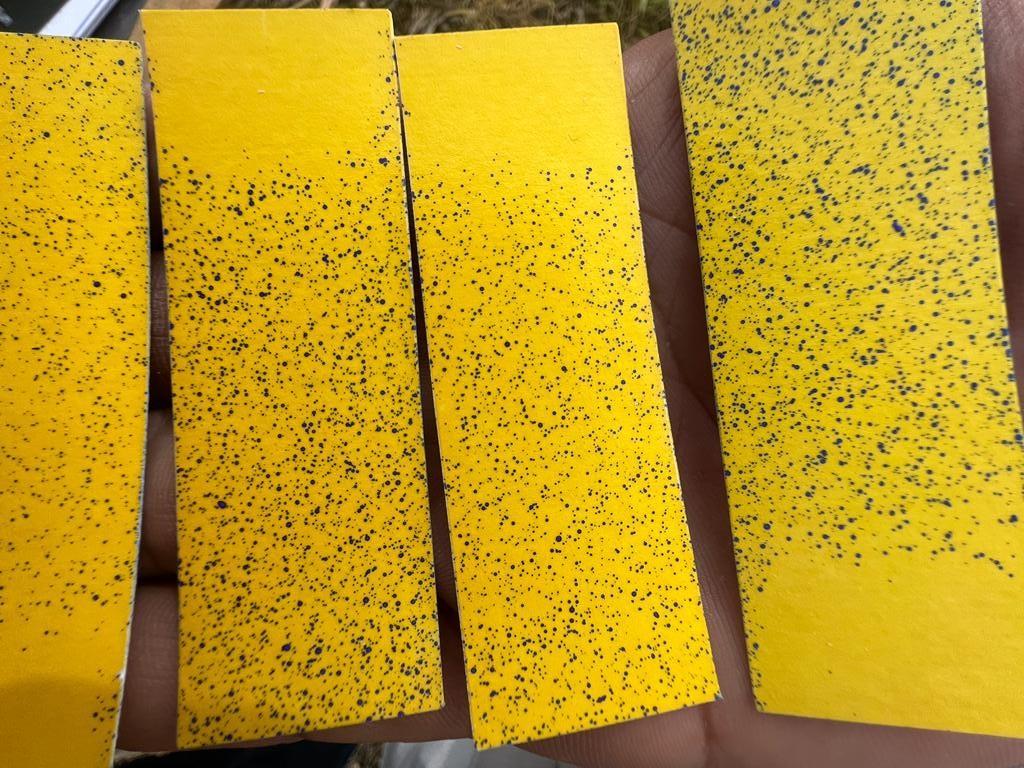

Pioneer in using full stainless steel in pumps, valves, and spray booms, eliminating corrosion of aluminum parts and extending service life. Our 316 L stainless-steel wind pump offers unmatched flow-pressure ratio and durability, servicing ~5,000 aircraft worldwide and 95% of Brazil’s agro-aviation fleet. Our rotary atomizer is the world’s leading tech for aerial application of insecticides, fungicides, and foliar fertilizers, field-tested on over 500 aircraft across various crops. Continuous R&D with pilots, mechanics, and agronomists keeps us #1 in liquid application.

The only Latin American maker of aerial firefighting gates, installed on Cessna 188, Embraer Ipanema, Air Tractor 402–802, and Thrush 510. With 15+ years in Brazil’s biomes—Amazon, Cerrado, Atlantic Forest, Pantanal, Caatinga, Pampas—and expanding to Argentina, Africa, and Europe. Led the first global research on effective deposition and coverage with agricultural aircraft, and invests in pilot training, workshops, conferences, and regulatory advocacy to boost firefighting efficacy.

Developed for agricultural aviation, our stainless-steel pumps now serve sprayers, trucks, tractors, IBCs, and fixed stations. 100% stainless construction resists acids, salts, and harsh solvents. Trusted by Brazil’s largest formulators and exported to Canada, USA, and Africa for –20 °C to +45 °C operation. Customizable with hydraulic, electric, or combustion motors, various flanges, quick-couplers, and high-flow or high-pressure rotors.

Drawing on decades of agro-aviation and industrial experience, our stainless-steel pumps handle corrosive modern mixtures with hydraulic performance tailored to narrow or wide booms. Modular Z 00233 H and Z 00243 H series (08, 11, 16 cm³) work dry briefly and self-lubricate with hydraulic oil. Compact and easy to install on John Deere, Case, Stara, Valtra, and New Holland machines, bringing aero-engineering durability and national support to the field.

Authorized distributors across Brazil, Latin America, North America, Africa, and Oceania.

Partner workshops and specialists for calibration and maintenance.

Custom solutions with aircraft and agricultural machine manufacturers.

First Brazilian aero-agricultural equipment maker certified by ANAC (Production Organization Certificate), one of fewer than 10 nationwide and the only one in Paraná. Our COP aligns with FAA and EASA approvals, ensuring technical and documentary compliance for aerospace production, and elevates quality and safety standards in agricultural machinery.

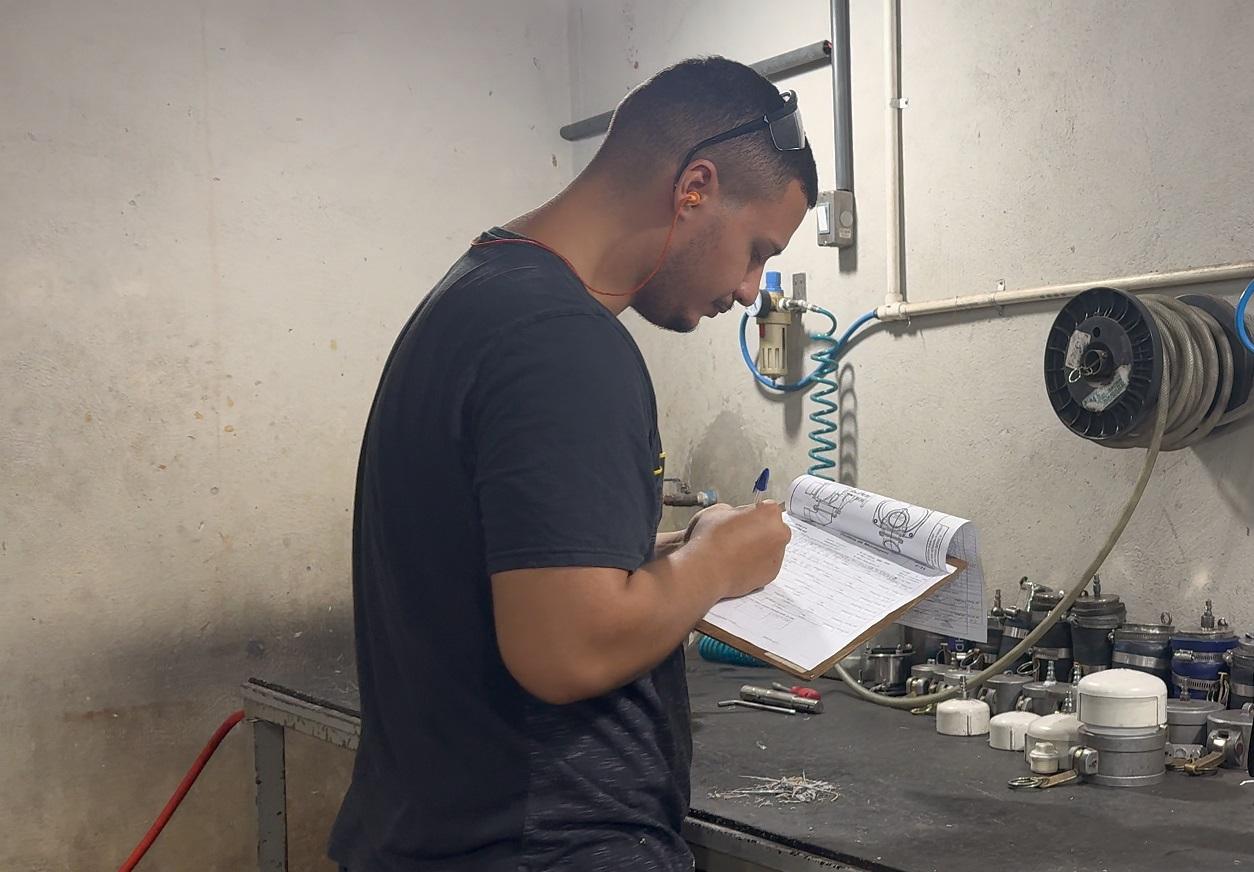

Over 2,500 unique products undergo a five-step inspection process—100% checked individually, no sampling:

We maintain a 10-year traceability program logging raw material lots, each production step, assembly phases, and final delivery—enabling targeted recalls and process improvements unmatched in our sector.

Our Quality Department, separate from Inspection, has five specialists managing processes, ANAC audits, and training. They formalized workflows and integrated all teams into an aerospace-grade quality culture.

Zanoni Equipamentos © 2026 - All rights reserved