Zanoni Equipamentos started the development of rotary atomizers in the middle of the 2010s, at the request of its partners in the Brazilian agricultural aviation industry. Due to the demand for more efficient and resistant nozzles in Brazil, the company has been manufacturing a complete line of this type of equipment, bringing to the market the traditional durability of the Zanoni brand. After a lot of research and dialogue with the aeroagricultural operators, three models were launched and a fourth is under development, in order to satisfy the different needs of the aerial application:

| The success presented by the product generated a new work front within Zanoni Equipamentos. For presenting mechanical characteristics and an agronomic efficiency with standards of excellence, Zanoni rotary atomizers have come to be sought after by a large part of our global network of partners. This equipment has been seen as one of the most appropriate technologies for the application of insecticides and fungicides in Brazilian crops, in addition to being used for some special applications that require different parameters, such as mosquito control in the USA, locust control in Africa and forest pest management in Canada. |  |

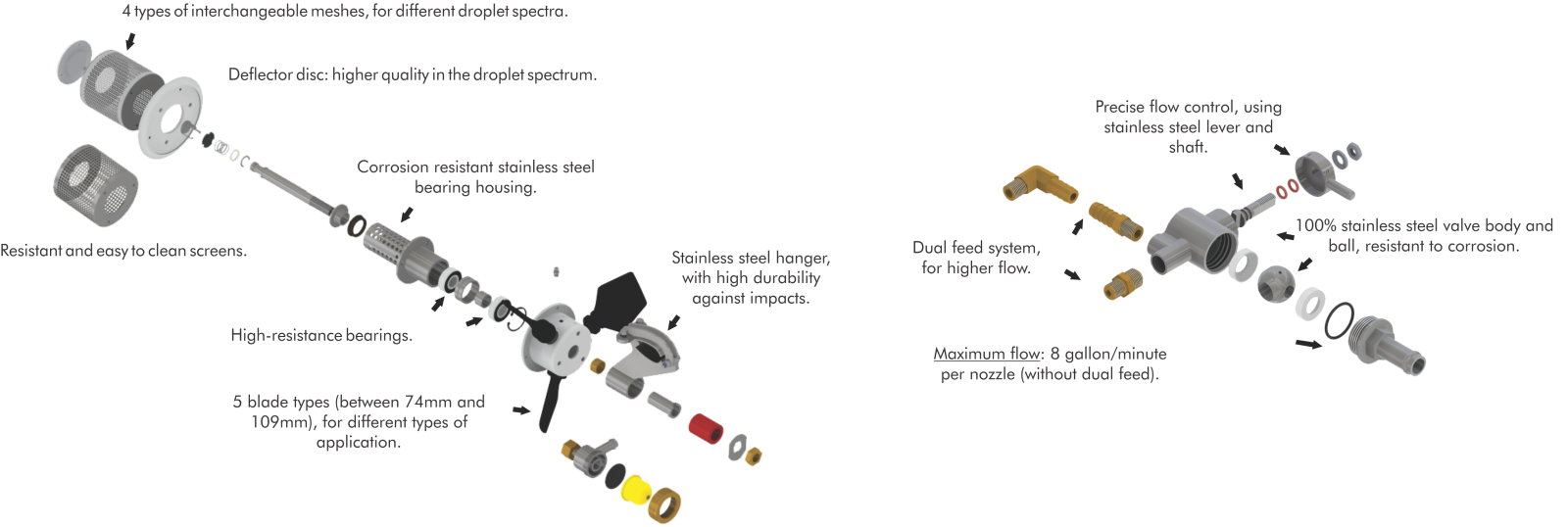

After years of study, Zanoni Equipamentos® rotary atomizers were developed through high quality and precision procedures, using materials resistant to the most corrosive products used in aerial spraying. They are equipped with a cylindrical stainless steel screen and are available in several mesh option, capable of producing the spectrum of drops required for each type of operation:

|

|

Since the beginning of the work in the line of rotary atomizers, Zanoni Equipamentos maintains a constant dialogue with agronomists and other scientists, searching to improve the quality in aerial application. Several researches, in the field and in the laboratory, have been financed by the company, offering accurate data to our partners regarding the spectrum of droplets provided by the Zanoni atomizer.

Work has been carried out with some of the world's leading specialists in the areas of aerial spraying, low volume application and the droplet science. All of them have indicated that the Zanoni rotary atomizer presents safe and reliable standards for the most varied application conditions, including different types of aircraft and different types of products.

|

|

|

|

|

Research conducted by Alan McCracken with Zanoni M3 on Air Tractor 402 was featured in the AgAir Update magazine (September/2020). |

New parameters in aerial application in the Brazilian market were highlighted in the AgAir Update magazine (September/2021). | Research at the Pesticide Application Technology lab, University of Nebraska-Lincoln (USA), was featured in the Agair Update (April/2021). | Project carried out by PhD Henrique Campos with M14 on Embraer Ipanema evaluated the quality of applications in several parameters. |

|

|

|

|

| Zanoni supported a cycle of Aircraft Clinics in different aerial application companies across Brazil, initiative that united research, training and pre-season calibration. | Project carried out by Rodrigo Franco Dias (UFSM, ConnectFarm) with M3 on Air Tractor AT402 evaluated the quality of applications in several parameters. | Zanoni atomizers were featured at the National Agricultural Aviation Association (USA) convention in 2021, where we held a seminar on aerial application technologies. | Zanoni was a speaker at the second Brazilian Academy of Aerial Application Technologies, promoted by IBRAVAG, where we discussed perspectives and challenges on low volume. |

|

|

|

|

| A research project was carried out together with one of the largest soybean and cotton producers on the planet, for the development of atomizers to be used in high-speed aircraft. | Researches are being carried out with our atomizers for mosquito control (with ultra-low volume ad-ulticide application), with many positive feedback from US operators. | A project carried out in East Africa is using Zanoni atomizers for locust control, in a work spearheaded by the Food and Agriculture Organization of the United Nations (FAO). | Field research conducted by customers has indicated excellent performance of Zanoni atomizers on turbo aircraft, including Air Tractor and Thrush. |

|

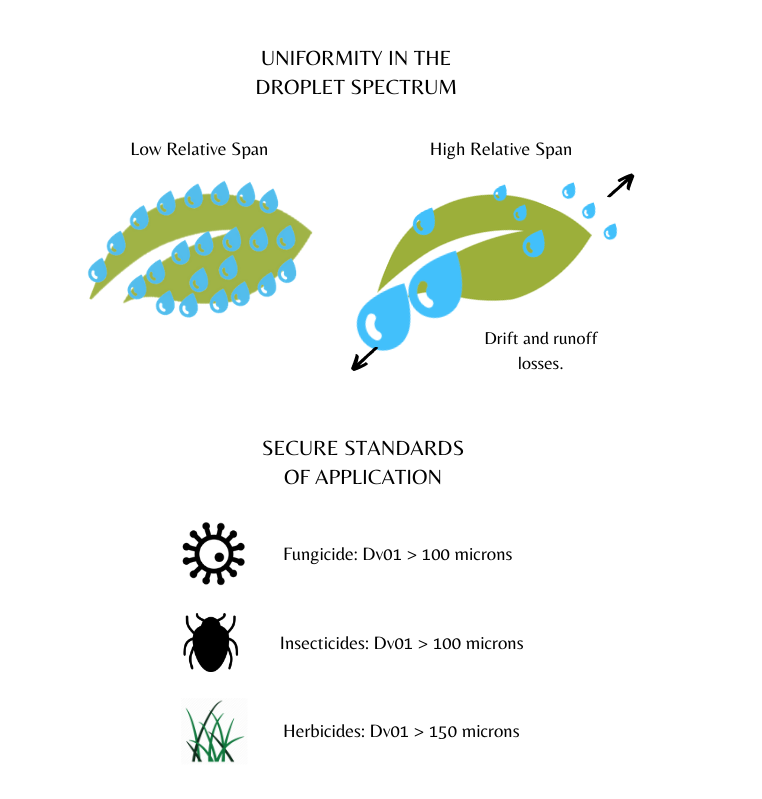

Despite the initial concern with the size of droplets offered by spraying technologies normally being their volumetric median diameter (VMD), the quality of the application is mainly related to the uniformity of the droplet spectrum (relative span) and the absence of very fine or very thick droplets. A nozzle may be able to offer a VMD suitable for a particular type of application, however, if it does not have a low relative span (RS), the quality of the application will be compromised due to the loss of very fine or very thick drops. Thus, it is not enough for a particular nozzle to offer different configurations for different VMDs without the relative span remaining low in its various settings. In addition to uniformity, it is important to take into account the indicator called Dv01, which measures the diameter which 10% of the volume that was sprayed had drops smaller than it (that is, the 10% of very fine drops, susceptible to drift). An application with DV01 above 100 microns is recommended for insecticide and fungicide and above 150 micron for herbicides. |

|

In addition to field tests indicating that the Zanoni rotary atomizers show a standard of excellence in the indicators mentioned above, we innovated by bringing to Brazil the first calculator for forecasting the droplet spectrum. With this tool, it will be possible to obtain an approximation of the different parameters (VMD, AR, Dv01 and Dv09) offered by the three Zanoni atomizers (M2.5, M3 and M14), in different equipment configurations and at different flight speeds.

The work is the result of a major research project carried out in the wind tunnel of the Laboratory of Technologies for the Application of Pesticides, at the University of Nebraska-Lincoln, which was made possible by our North American distributors from Turbine Conversions. Conducted by some of the world's leading experts in the field of droplet science (with an agronomic focus), the study offers a large database to assist our agricultural aviation partners around the world.

In addition to the droplet spectrum, information on the position of the nozzles and determination of the ideal swath width is of great importance for aerial spraying, since the adequacy of the range guarantees the absence of phytotoxicity in the crop (due to the overlapping of the strips) and prevents failures in pest and disease control. The ideal for uniformity of the range, which is calculated by the CV indicator is that it is always less than 20% and, the smaller it is, the more uniform and efficient the application is.

In partnership with PhD Henrique Campos (Sabri), Zanoni Equipamentos has been carrying out a large amount of field research to evaluate the best possible configurations with each Zanoni atomizer in each specific type of agricultural aircraft. The data on the ideal swath for each type of adjustment of the Zanoni atomizer are offered to each of the customers according to the availability of the information.

In addition to the joint research work carried out to provide more information to our customers, Zanoni Equipamentos and SABRi have a partnership to provide the best possible agronomic assistance to operators of the Zanoni atomizer. Our customers have a special price for hiring the Aircraft Clinic and for the purchase of Aircraft Clinic kits, and also have access to the online agronomic advice provided by Henrique Campos and José Luis Santos.

The DoPro Agricultural Aircraft Clinic assists in determining the ideal swath width for the aircraft, in checking product distribution losses, in dimensioning the drift potential and in characterizing the size of the droplets. The work is done on a customer basis with a series of special technologies developed by the American Department of Agriculture (USDA). In addition to DoPro Clinic, operators of Zanoni rotary atomizers have access to a special discount for the purchase of assessment kits for their aircraft, carrying out the data collection work on their own for further analysis by specialists in aerial application. The Aircraft Clinic kit allows remote evaluation. With the aid of an online app, the interested party collects the deposition sample from the aircraft and sends it to the analysis laboratory. After analysis, the report is presented in the app and can also be accessed by the QRCode sticker made available to the aircraft. The Zanoni / SABRi partnership also offers a constant communication channel between users and our team, to obtain technical assistance (agronomic and mechanical), clear up doubts and share information and experiences between pilots and technicians.

Useful links:

HATFIELD, Ann. Turbine Conversions and Zanoni Equipamentos Atomizer Testing at the Pesticide Application Technology Lab, University of Nebraska North Platte. Agair Update, April 2020.

ZANONI, Lucas. Low Volume Revolution. Agair Update, September 2021.

Zanoni Equipamentos © 2026 - All rights reserved